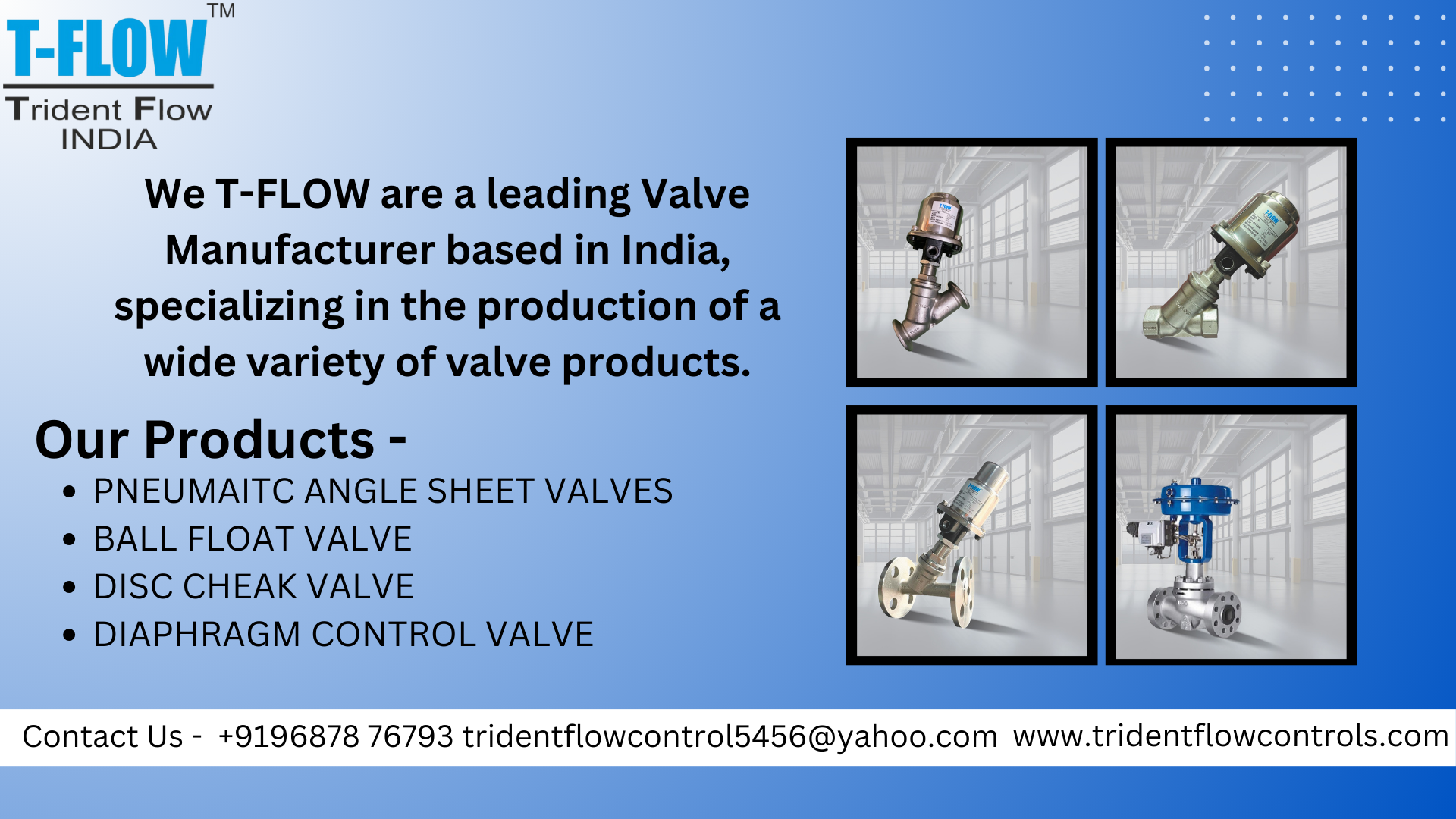

Angle Seat Valve Manufacturers in India

Angle

Seat Valve Manufacturers in India

Angle seat valves are pneumatically or electrically

actuated valves designed for high-cycle, high-flow control of liquids, gases,

and steam. Recognized for their reliability, durability, and fast response

times, these valves operate with a piston actuator that lifts a seat at an

angle, allowing unobstructed flow with minimal pressure drop.

Top angle seat valve manufacturers in India offer

precision-engineered solutions crafted from stainless steel or brass with PTFE

or other chemically resistant seats — ideal for industries like food

processing, chemical plants, textile manufacturing, pharmaceuticals, and water

treatment.

Indian manufacturers are known for delivering

cost-effective, customizable, and export-quality valve solutions that meet

international standards (ISO, CE, RoHS).

Features

with Uses

|

Feature |

Use/Benefit |

|

Angled Seat Design (45° or 90°) |

Provides high flow rates with low pressure drop and resistance to water hammer. |

Pneumatic or Electric Actuation |

Offers fast and remote operation for automation systems. |

|

Stainless Steel/Brass Body Options |

Ensures corrosion resistance for aggressive or hygienic

environments. |

|

PTFE/EPDM/Graphite Seats |

Allows compatibility with hot water, chemicals, steam, and

compressed air. |

|

Normally Open / Normally Closed Types |

Suitable for different control and fail-safe conditions. |

|

High Lifespan (Millions of Cycles) |

Ideal for repetitive use in industrial automation systems. |

|

Visual Position Indicator |

Shows valve position (open/close) for operator

convenience. |

|

Threaded, Flanged, or Tri-Clamp Ends |

Flexible installation options for piping systems. |

|

Temperature Resistance (up to 180–220°C) |

Suitable for steam and thermal oil systems. |

|

Low Maintenance |

Simple design reduces downtime and servicing costs. |

Applications

Angle seat valves are versatile components used in:

- Food

& Beverage Industry: Clean-in-place (CIP) systems, fluid filling lines, and beverage flow control.

- Pharmaceuticals:

For sterile process control and drug formulation equipment.

- Chemical

Industry: Handling aggressive or corrosive fluids, acids, and

solvents.

- Textile

Processing Units: Steam and dye flow control in dyeing machines.

- Water

Treatment Plants: Controlling filtered water and chemical dosing

lines.

- HVAC

& Thermal Systems: Regulating hot water and steam in industrial

heating.

- Compressed

Air Systems: Controlling pneumatic actuators and tools.

- Breweries

& Distilleries: Used for high-flow valve control in hygienic

environments.

- Automated

Manufacturing: Integration in robotics and packaging machinery.

- Steam

Boilers and Autoclaves: High-pressure steam control for safety and

process control.

Top 10

FAQs – Angle Seat Valve Manufacturers in India

- What

is an angle seat valve?

An angle seat valve is a pneumatically or electrically operated valve designed to control the flow of fluids, gases, or steam at high flow rates. - Why

choose an angle seat valve over a regular globe valve?

Angle seat valves offer faster response, higher flow capacity, and longer service life, especially in automated systems. - What

materials are commonly used by Indian manufacturers?

Stainless steel (304/316), brass, and PTFE or EPDM seals are most commonly used. - Are

Indian-made angle seat valves suitable for international markets?

Yes, many manufacturers export globally and comply with ISO, CE, and RoHS certifications. - Can

these valves handle steam or high-temperature fluids?

Yes, high-quality models can withstand temperatures up to 180–220°C and are widely used for steam applications. - What

actuator types are available?

Pneumatic (single or double acting) and electric actuators are available based on process requirements. - Are

angle seat valves suitable for food-grade applications?

Yes, food-grade models with hygienic tri-clamp ends and FDA-approved seats are available. - How

are they controlled in an automated system?

Typically controlled via a solenoid valve or PLC in pneumatic systems. - Do

they require regular maintenance?

Minimal maintenance is needed. Periodic seat inspection and cleaning are usually sufficient. - What

sizes do Indian manufacturers offer?

Standard sizes range from ½” to 4”, with custom options available upon request.

Contact

Us For More Details On :

Call –

9687876793

Email -

tridentflowcontrol5456@yahoo.com

Website –

www. tridentflowcontrols.com

Address -

90, Vrundavan Estate, Opp. Vijay Estate, Bhikshuk Gruh, Odhav, Ahmedabad-382

415.

YouTube -

www.youtube.com/@tridentflowcontrols

Instagram

- www.instagram.com/trident_flow

Filter Using Blog Tags

Quick Links

Our Products

Get In Touch

90, Vrundavan Estate, Opp. Vijay Estate, Bhikshuk Gruh, Odhav, Ahmedabad-382 415.

tridentflowcontrol5456@yahoo.com

tridentflowcontrol5456@yahoo.com

9687876793

T-FLOW 2023-2024 | All Rights Reserved. Design and Developed by Industry Lead -8000121171