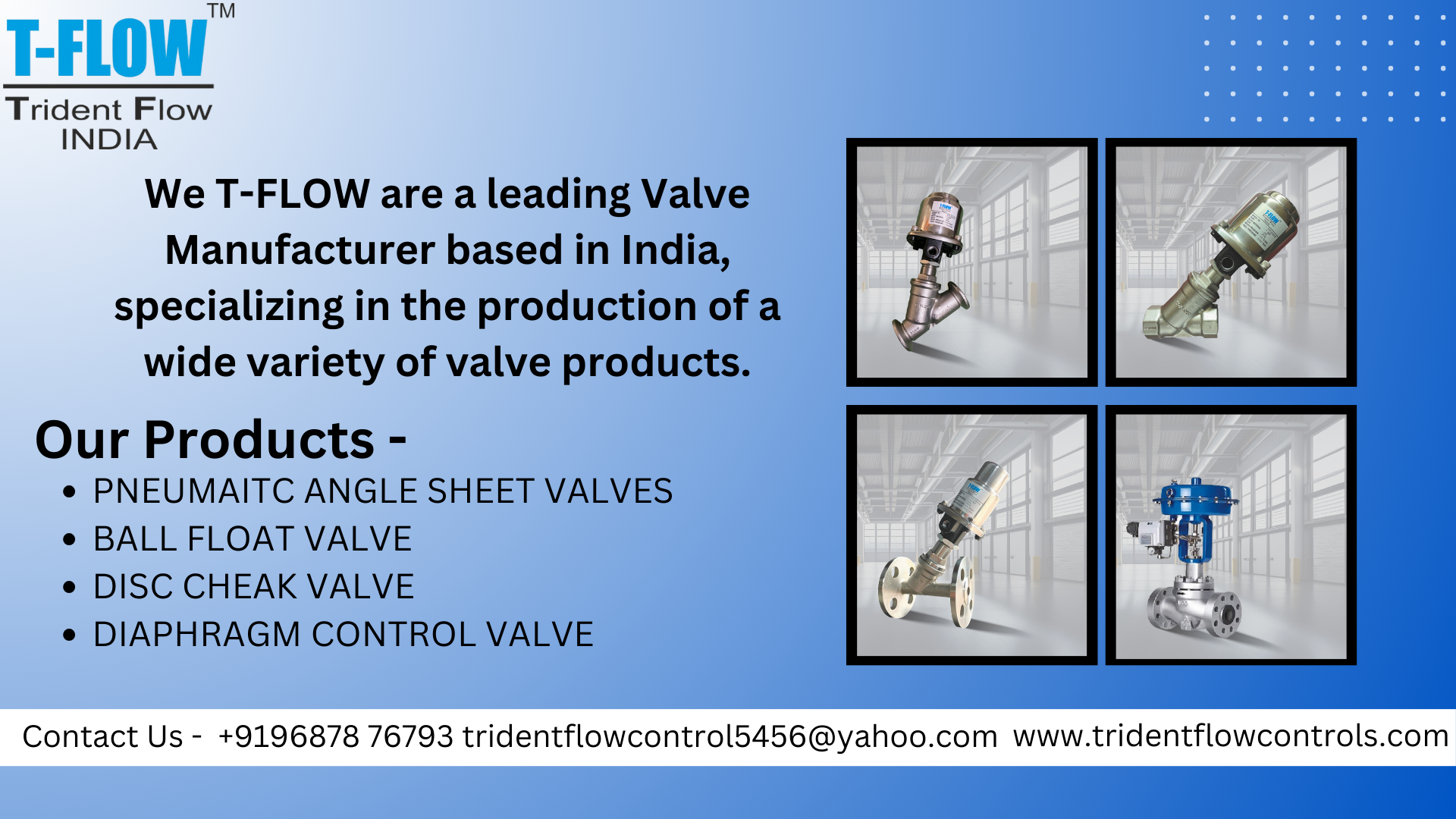

Diaphragm Valve for Chemical Industries in India

T-FLOW supplies high-performance diaphragm valves for chemical industries in India, engineered for aggressive media, corrosive slurries, and high-purity streams. With hygienic isolation, precise throttling, and reliable shut-off, our valves protect downstream equipment and ensure process safety across acid, alkali, solvent, and brine handling lines.

What is a Diaphragm Valve in Chemical Processing?

A diaphragm valve uses a flexible elastomer or PTFE diaphragm to separate the process media from the bonnet and actuation mechanism. This sealed flow path prevents contamination and fugitive emissions—critical for chemical plants where leak-tight integrity, corrosion resistance, and clean operation directly affect product quality and EHS compliance.

Common Types for Chemical Service

- Weir-type diaphragm valves for accurate throttling and CIP/SIP compatibility.

- Straight-through (full-bore) valves for viscous fluids and slurries with minimal pressure drop.

- Pneumatic diaphragm valves with positioners for automated flow control loops.

- Manually operated diaphragm valves for on/off isolation in utility and dosing lines.

- PTFE/EPDM-lined diaphragm valves for acids, caustics, and solvents in corrosive duty.

Key Features & Specifications

- Leak-tight bonnet isolation with flexible diaphragm (EPDM, PTFE, NBR, FKM).

- Body materials: CI/SG iron, CF8/CF8M stainless steels, and alloy options.

- End connections: flanged, tri-clamp, or threaded as per line standards.

- Working pressure/temperature ranges tailored for chemical compatibility.

- Manual handwheel or pneumatic actuator with optional limit switches/positioners.

Applications in Chemical Industries

- Acid/alkali transfer lines in chlor-alkali, dyes & pigments, and specialty chemicals.

- Dosing and metering skids for reagents, catalysts, and neutralization systems.

- Solvent handling with sealed isolation to minimize emissions and vapor loss.

- Water treatment, DM/RO plants, and effluent neutralization at chemical sites.

- Pharma-chemical and fine chemicals requiring hygienic, cleanable flow paths.

Why Choose T-FLOW for Chemical Duty Valves

- Enhanced safety via diaphragm isolation—no packed gland leakage to atmosphere.

- Excellent corrosion resistance with PTFE/EPDM linings and SS bodies.

- Accurate throttling for pH control, dosing, and flow regulation loops.

- Lower maintenance—few wetted moving parts and easy diaphragm replacement.

- Custom builds for Indian standards, site conditions, and OEM skids.

Trusted Manufacturer & Supplier in India

As a leading diaphragm valve manufacturer for chemical industries in India, T-FLOW delivers ISO-compliant valves for corrosive service, with options like PTFE-lined weir types, GMP-friendly designs, and automated pneumatic packages. Our valves are field-proven across chemical clusters in Gujarat, Maharashtra, and beyond.

Maintenance & Safety Tips

- Match diaphragm material (EPDM/PTFE/NBR/FKM) to the chemical compatibility chart.

- Inspect diaphragms for creep or blistering after thermal/chemical excursions.

- Use clean, dry instrument air for pneumatic actuators and check stroke regularly.

- Flush lines after shutdowns to avoid crystallization or polymer build-up.

- Follow preventive replacement intervals to minimize unplanned downtime.

FAQs – Diaphragm Valve for Chemical Industries India

Contact Details

Talk to our specialists today for tailored solutions and fast assistance.