Introduction to Diaphragm Valves for Industrial Automation in India

For OEM skid builders and process plants across India, diaphragm valves for industrial automation deliver reliable shut-off, precise throttling, and hygienic isolation of media. With clean separation between the actuator and process, these valves thrive in chemical dosing, water & wastewater, pharmaceuticals, and food & beverage. When paired with pneumatic or electric actuators, positioners, and feedback switches, they integrate seamlessly with PLC/SCADA systems, enabling remote operation, fail-safe control, and data-driven maintenance.

What is a Diaphragm Valve?

A diaphragm valve regulates flow using a flexible diaphragm that presses against a weir or seat. The diaphragm isolates the media from moving parts, minimizing contamination and corrosion. In automated systems, the valve is driven by a pneumatic or electric actuator and may include a positioner (4–20 mA), limit switches, and digital/analog feedback for closed-loop control. This makes diaphragm valves ideal for aggressive chemicals, slurries, and sterile processes common in Indian industry.

Types of Automated Diaphragm Valves

- Pneumatic actuated diaphragm valves (spring-return / double-acting) with NAMUR solenoid options.

- Electric actuated diaphragm valves for plants lacking instrument air or needing precise step control.

- Weir-type valves for throttling and hygienic dut straight through for slurry/viscous media.

- PTFE/EPDM diaphragms matched to chemical compatibility and temperature range.

- Automation accessoriespositioners, limit switch boxes, proximity sensors, and air filter-regulators.

Key Features for Industrial Automation

- PLC/SCADA friendly with 4 20 mA position feedback and digital status outputs.

- Fail-open / fail-close safety via spring-return pneumatic actuators.

- Corrosion-resistant bodies (CI/SS/alloy) and PTFE-lined options for aggressive media.

- Fast response with low air consumption; IP65/IP67 actuator housings.

- Sanitary design for CIP/SIP in pharma and food applications.

Applications of Automated Diaphragm Valves

- Chemical dosing skids, neutralization systems, and bulk chemical transfer.

- Water & wastewater treatment—RO/UF, ETP/STP process control and sludge lines.

- Pharmaceutical and biotech CIP/SIP loops requiring sterile isolation.

- Food & beverage process lines handling syrups, brines, and cleaning agents.

- Pulp & paper, mining, and general process industries with abrasive slurries.

Benefits of Choosing Automated Diaphragm Valves

- High reliability and longer service life due to diaphragm isolation.

- Improved plant safety with defined fail-safe positions and remote operation.

- Lower lifecycle cost—reduced maintenance and quick diaphragm replacement.

- Excellent chemical compatibility and hygienic performance.

- Easy integration with existing control architectures and IIoT monitoring.

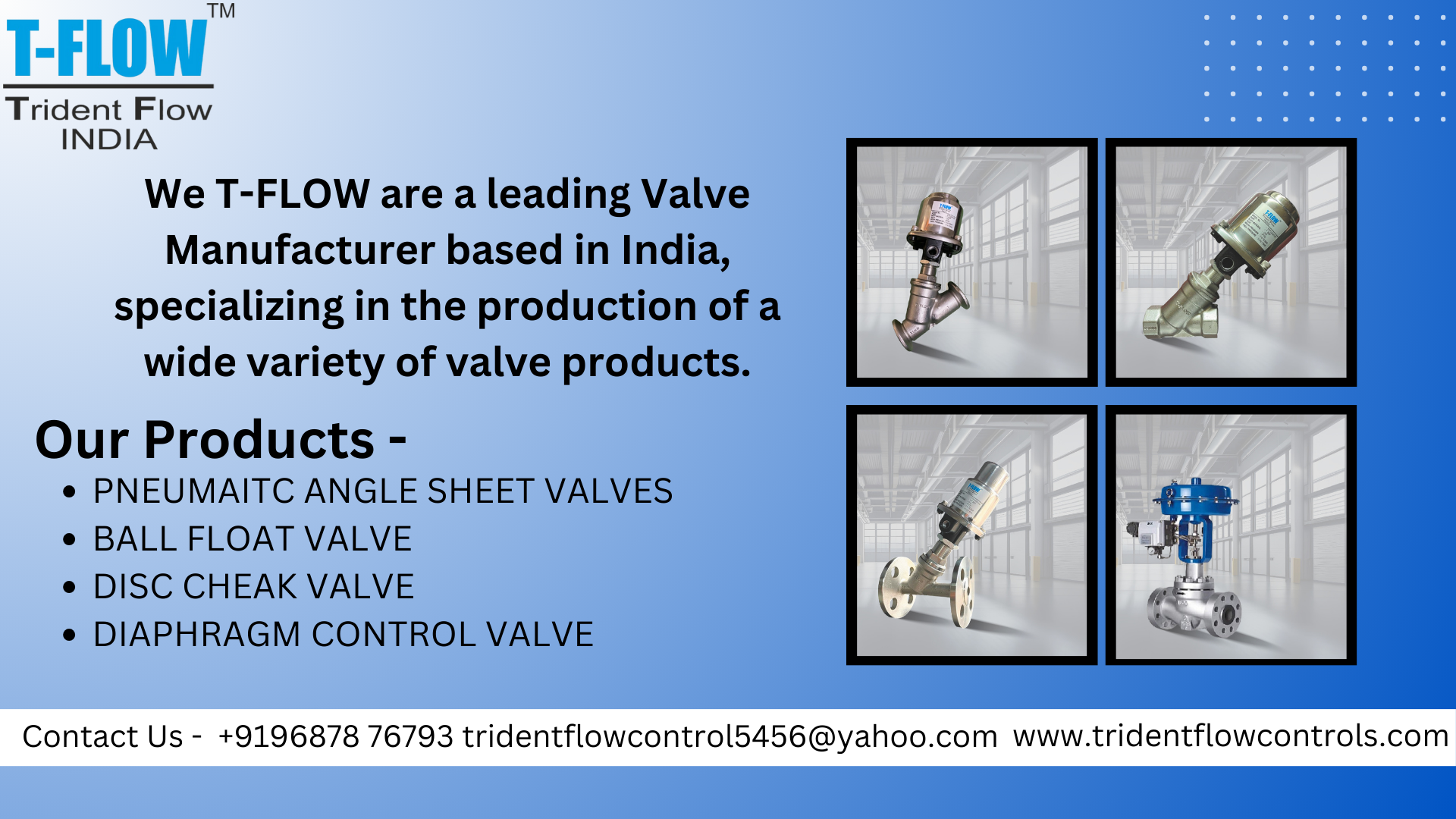

Top Manufacturers and Suppliers in India

T-FLOW is recognized among leading suppliers of automated diaphragm valves in India, offering pneumatic and electric actuation, PTFE-lined variants, and hygienic designs suited for pharma, chemical, and water applications. From compact OEM skid valves to large-bore plant installations, T-FLOW delivers reliable control solutions engineered for Indian process conditions.

Maintenance and Safety Tips

- Match diaphragm material (EPDM, PTFE, FKM, NBR) to media and temperature.

- Use clean, dry instrument air; install FRL units before pneumatic actuators.

- Set positioners per manufacturer guidelines; verify 4–20 mA scaling.

- Check actuator travel stops and limit switches after commissioning.

- Inspect diaphragms periodically; replace at first signs of creep or cracking.

FAQs – Diaphragm Valves for Industrial Automation

Contact Details

Talk to our specialists today for tailored solutions and fast assistance.