Introduction to Gujarat-based Diaphragm Valve Manufacturers

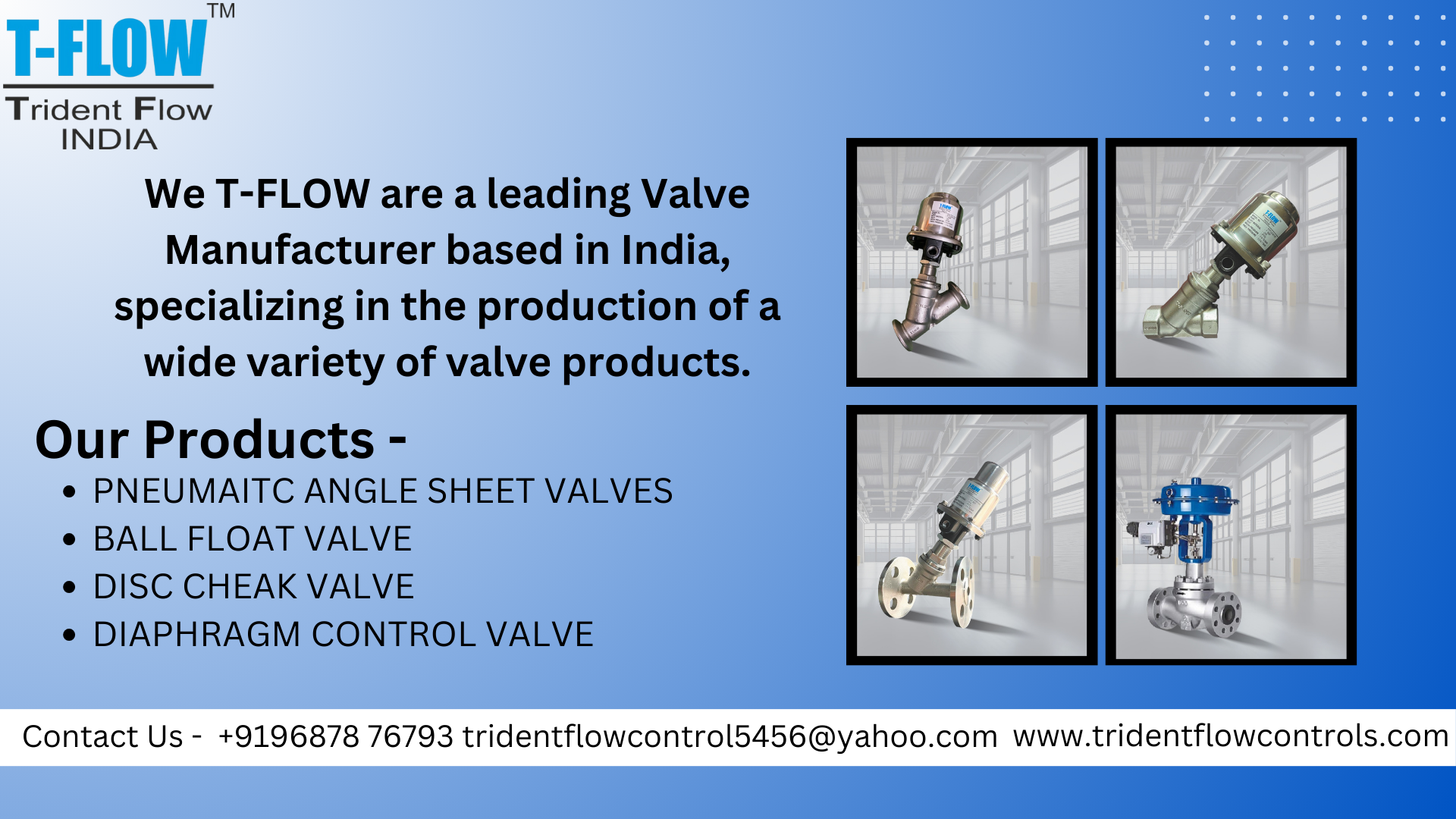

T-FLOW is a trusted diaphragm valve manufacturer from Gujarat, serving process industries across Ahmedabad, Vadodara, Vapi, Rajkot, and Surat. Our valves are engineered for precise throttling, bubble-tight shut-off, and long service life in chemical, pharma, food, water treatment, and allied sectors. With robust materials and hygienic designs, we deliver reliability, safety, and efficiency for demanding Indian and export projects.

What is a Diaphragm Valve?

A diaphragm valve regulates flow using a flexible diaphragm that isolates the process media from moving parts. This contamination-free construction offers smooth control, tight shut-off, and reduced maintenance. It is ideal for corrosive, abrasive, sterile, or slurry applications commonly found in Gujarat’s chemical corridors and industrial estates.

Types of Diaphragm Valves

- Manual diaphragm valves for dependable on/off and throttling control.

- Pneumatic diaphragm valves with actuator/positioner for automation.

- Weir (A-type) valves for hygienic duty and accurate modulation.

- Straight-through (B-type) valves for slurries and abrasive media.

- PTFE/EPDM-lined variants for chemical resistance in acid/alkali services.

Key Features and Specifications

- Leak-tight isolation via reinforced elastomer/PTFE diaphragm.

- Body options in CI/DI, WCB, CF8/CF8M and alloy steels.

- End connections: screwed, flanged (ANSI/ASME, PN), tri-clamp (hygienic).

- Compatible with aggressive chemicals, ultra-pure water, and slurries.

- Automation-ready with pneumatic actuators, limit switches, and positioners.

Applications in Gujarat Industries

- Chemical & petrochem clusters (Dahej, Ankleshwar, Jhagadia) handling acids, brines, and solvents.

- Pharma & biotech in Ahmedabad/Baroda requiring sterile, cleanable valves.

- Food & beverage plants for hygienic processes and CIP/SIP compatibility.

- Water & wastewater treatment plants in municipalities and industrial estates.

- Pulp & paper, dyes & intermediates, and mining slurry lines.

Why Choose T-FLOW for Diaphragm Valves in Gujarat

- Local engineering support with quick delivery across Gujarat.

- Hygienic, corrosion-resistant designs ensuring process integrity.

- Low lifecycle cost due to simple mechanism and easy diaphragm replacement.

- Custom builds and automation packages for brownfield and greenfield projects.

- Compliance with global standards and rigorous in-house testing.

Top Manufacturers and Suppliers in Gujarat

T-FLOW stands among leading Gujarat diaphragm valve manufacturers, delivering manual and pneumatic weir/straight-through valves, PTFE-lined designs, and hygienic tri-clamp options. Our Ahmedabad facility supports specification review, sizing, and actuation—serving EPCs and end-users across Gujarat’s key industrial hubs.

Maintenance and Safety Tips

- Inspect diaphragms for fatigue or chemical attack at defined intervals.

- Verify flow direction arrows and ensure correct installation torque.

- Use compatible elastomer/lining materials per chemical resistance charts.

- Keep actuator air clean/dry; set travel stops and positioners correctly.

- Maintain a spare diaphragm kit and follow OEM replacement procedures.

FAQs – Gujarat-based Diaphragm Valve Manufacturers

Contact Details

Talk to our specialists today for tailored solutions and fast assistance.